|

| Mold in the making |

When I planned my Lego Star Wars Millenium Falcon cake's execution, I searched online for ready-made Lego molds, and then possibilities to create my own molds. Already then I came across this miracle substance called Silicone Plastique®, but ordering it from the USA would have become very expensive.

And when I saw them selling this at the Cake and Bake Show in Manchester, I just had to buy it :)

Now after the exhibition I visited the website of the company I bought this from, and noticed that it's possible to order this from them in England and even with very reasonable shipping costs.

I did also give a tip about this to one Finnish baking supply company, in case they might be interested in adding this to their selection :)

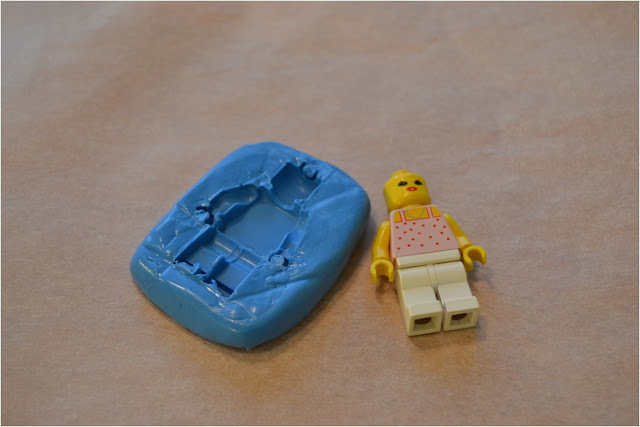

Making a mold with this putty is easy (although I think I chose a slightly too complicated subject as my first go with this).

The mold making putty consists of two parts, which are then mixed together in equal quantities which then starts up a chemical reaction which "hardens" the mold. As the salesman at the exhibition said though, you can't really talk about hardening but more like curing, as the finished mold is actually flexible as the traditional silicone molds are.

When the two parts have been mixed together so that the colours have mixed completely (the parts are different colours), it's possible to work with for about ten minutes, after which the mold is left to cure for about an hour.

The mold can also be used with molten sugar or isomalt, as (according to the manufacturer) it can withstand temperatures up to 230°C.

|

| Lego minifigure came out of the cured mold very easily |

|

| I tried the mold with sugar paste, and put it in the freezer for about 10 minutes before unmolding |

|

| The minifigure's hands didn't make it out of the mold, but then it didn't have time to harden either. Other than that, the mold worked out great. |

No comments:

Post a Comment